Swivel Joints

SEW manufactures the Swivel Joints are available in sizes 3/4″ through 3 ” up to 15,000 PSI non-stock cold working pressure.

The swivel joints is having the following features:

- Minimum flow restriction

- Grease retainer ring (ensures clean ball race)

- Available for standard and sour service

- Heavy duty hex head style ball loading plug

- Standard packing units (operating temperature to 2250 F)

- Superior hardened ball races ensure uniform surface hardness and depth for longer life under severe thrust and radial loading

- Standard Swivel Joints are provided with API line pipe threads Other end connections are available on request

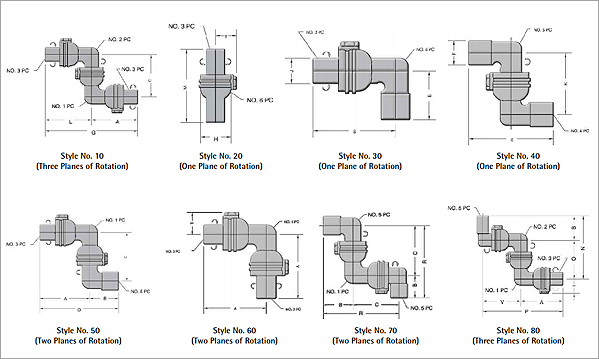

- All sizes are available in 8 styles, for 360 rotations in 1, 2 or 3 planes

Features & Benefits

The sour gas services require specially heat-treated steel.

Dual seal design isolates races and bearings

To isolate the races and bearings from line fluid, SEW use Fluoroelastomer or hydrogenated Nitrile packing, with stainless steel anti-extrusion ring, and secondary O-ring seal.

Streamlined bore minimizes flow restrictions

The quality of horizontal, round bore design minimizes pressure drop and turbulence.

To have better flow characteristics, swivel joints have extra-long radius elbows.

Leak detection port

In-between the primary packing and the secondary O-ring seal, Sour gas swivel joints have a leak-detection port. There is a need for packing change if leakage passes through the primary packing, which is forced through the port.

Integral Weco wing union ends

SEW manufacture sour gas swivel joints which are segmented in integral Weco wing union end connections, eliminating welding and minimizing turbulence.

Field repairable

To smooth running and functioning the swivel joints in a routine work, greasing is required at very low frequency. If packing, bearings, snap-in races, or ball plugs should need replacing, easy-to-use field repair kits are available.